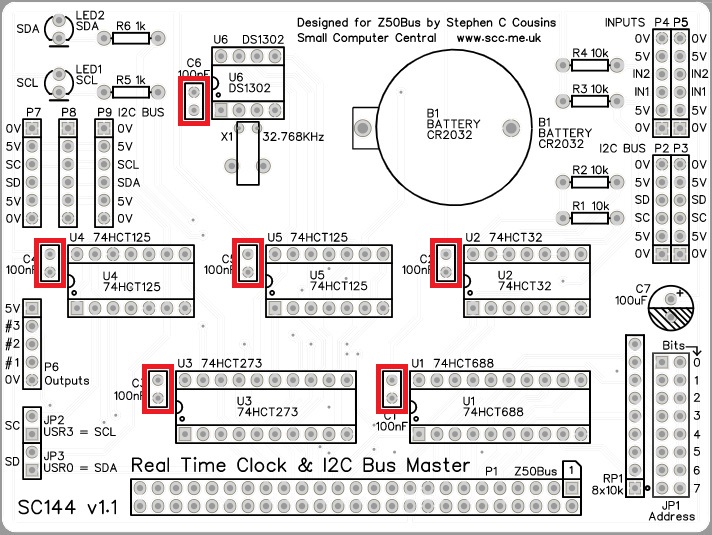

SC144 is a dual function card, providing a real time clock and an I2C bus master interface for the Z50Bus.

SC505 is a later version of this design

- SC144 – Forum (retro-comp)

- SC144 – Kit contents sheet (PDF)

- SC144 – Schematic v1.1 (PDF)

- SC144 – Gerber files (ZIP)

Suppliers

- SC144 – Kit (Tindie) – discontinued (replaced with SC505)

- SC144 – PCB (Tindie) – discontinued

Description

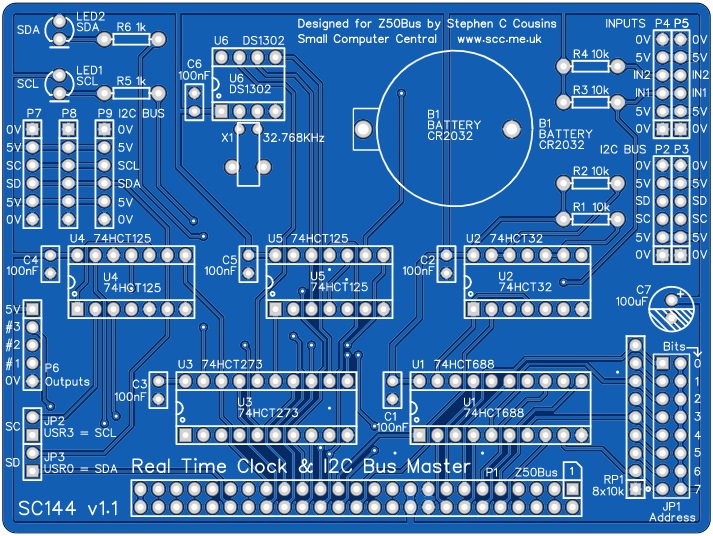

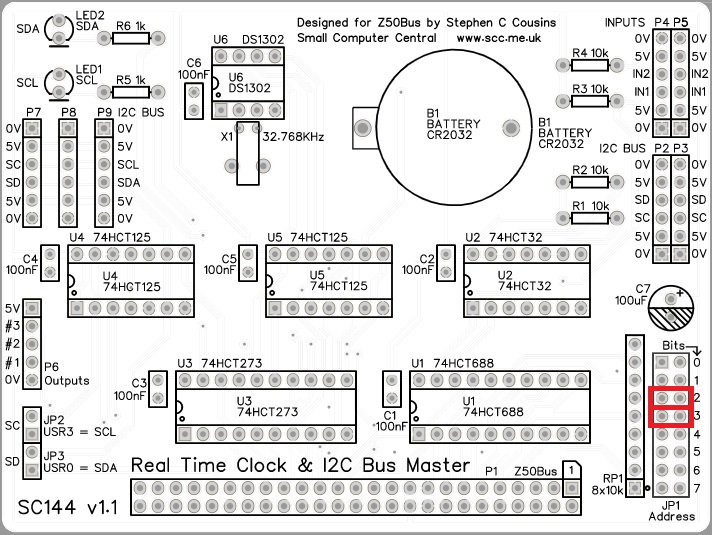

SC144 is dual function real time clock and I2C bus master interface card designed for the Z50Bus.

The main features of this design are:

- Z50Bus card measuring approximately 100mm x 75mm (4″ x 3″)

- Real time clock (RTC) using DS1302+ integrated circuit

- I2C bus master for 5 volt I2C devices

- Configurable I/O address with tight address decoding

- LED indicators to show the state of the I2C signals

- A variety of I2C bus connections (both male and female)

- Spare I/O lines available via header pins

- Jumpers to allow I2C signals to use the bus USER pins

User Guide

SC144 is dual function real time clock and I2C bus master interface card designed for the Z50Bus.

This module provides a real time clock and calendar using a battery backed DS1302+ integrated circuit. It also provides a 5-volt bit-bang I2C bus master.

A variety of connectors are included for the I2C making it easy to connect to the SC400 series of I2C modules as well as to many other I2C devices.

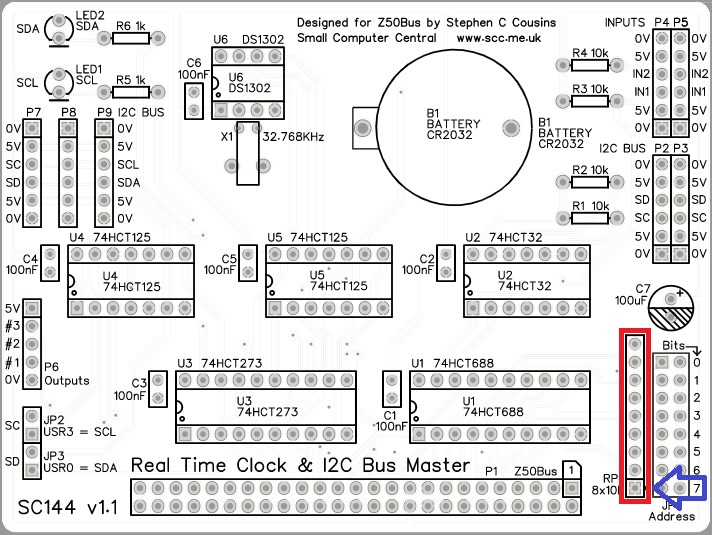

Address

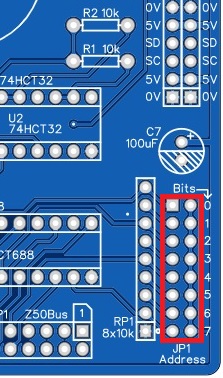

This card occupies one input / output address location. This can be set with jumper, JP1.

JP1, as illustrated to the left, provide jumper positions for all 8 I/O address bits.

Fit jumper shunts to any bit position you require to be high.

For example, to set the address to 0x0C (binary 0000 1100) fit a shunt to bit 2 and another to bit 3.

The current software assumes the address is 0x0C. This may change in the future as the recommended I/O map for Z50Bus systems is to have the processor or SBC use the lower 64 I/O addresses.

Bus signals

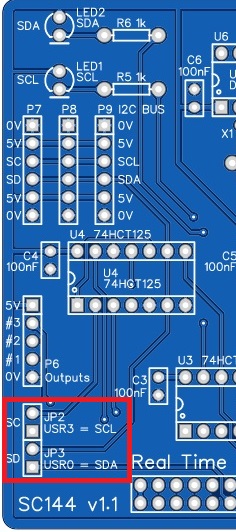

The two I2C signals, SCL and SDA, can optionally be connected to the Z50Bus USER signals USER0 and USER3, using jumpers JP2 and JP3.

Jumper shunts should only be fitted to JP2 and JP3 if you require the I2C signals to be output to the Z50Bus.

As the USER pins of the bus can be used for any purpose it is important to ensure that there are no other cards in the system that are using the pins for different signals.

Firmware support

Currently, the only firmware (ROM based) support is in RomWBW. This fully supports the real time clock (RTC) and does not any specific support for the I2C bus. Both the RTC and the I2C bus can of course be accessed directly with your own software.

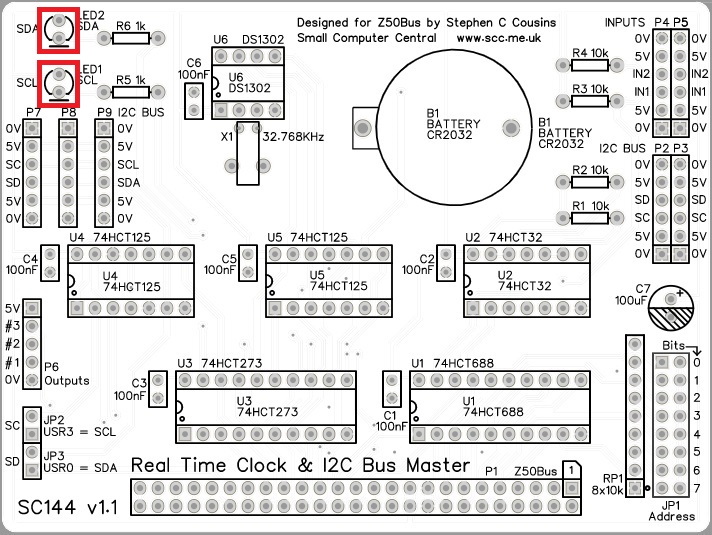

Light Emitting Diodes (LEDs)

The card has LEDs to show the state of the I2C serial data (SDA) and serial clock (SCL) signals. The LEDs light when the signals are low.

Example I2C software

The SC400 series of I2C modules is supported by and example / test program. This program has been written for use from the Small Computer Monitor.

Parts List

Printed Circuit Board

| Links |

| SC144, v1.1, PCB only (Tindie) |

| SC144, v1.1, Complete kit (Tindie) – discontinued |

| SC144, v1.1, PCB design files (OSHWLab) |

| SC144, v1.1, Gerber files (ZIP) |

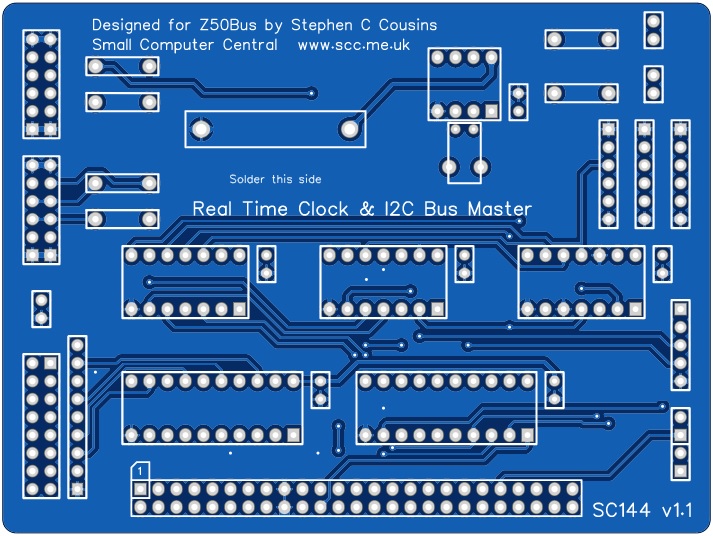

Assembly Guide

Experienced builders can just go ahead and populate the board. There shouldn’t be any surprises to catch you out.

This guide assumes you are familiar with assembling circuit boards, soldering, and cleaning. If not, it is recommended you read some of the guides on the internet before continuing.

First check you have all the required components.

Before assembling it is worth visually inspecting the circuit board for anything that looks out of place, such as mechanical damage or apparent manufacturing defects.

If you have a multimeter that measures resistance or has a continuity test function, check there is not a short on the power supply tracks. Connect the probes to each terminal of one of the capacitors, such as C1. This should be an open circuit, not a short.

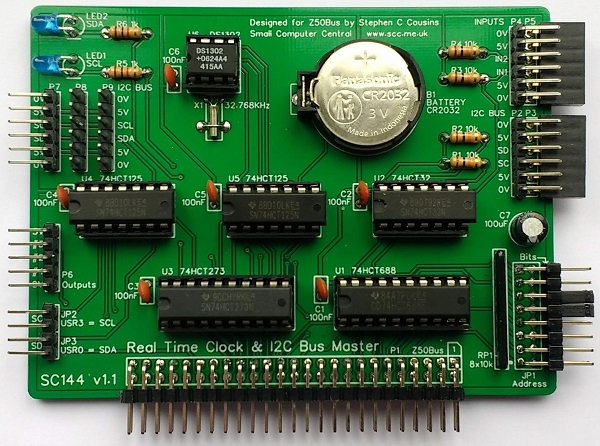

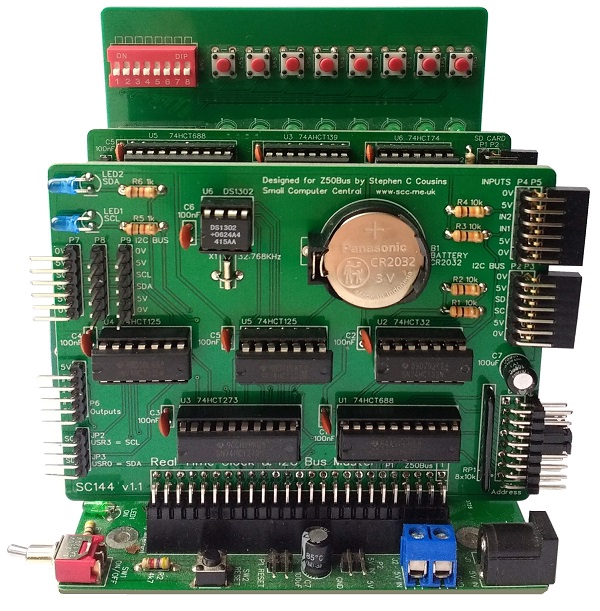

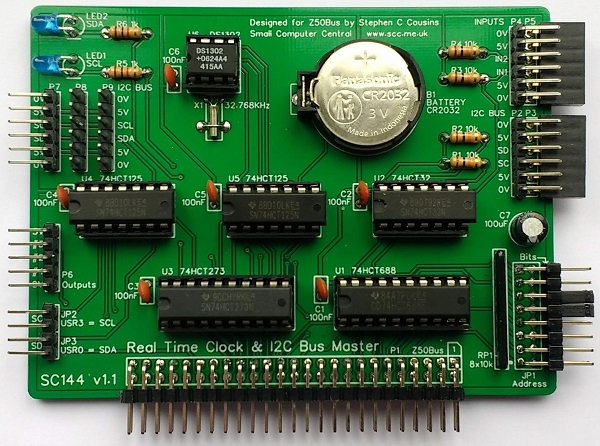

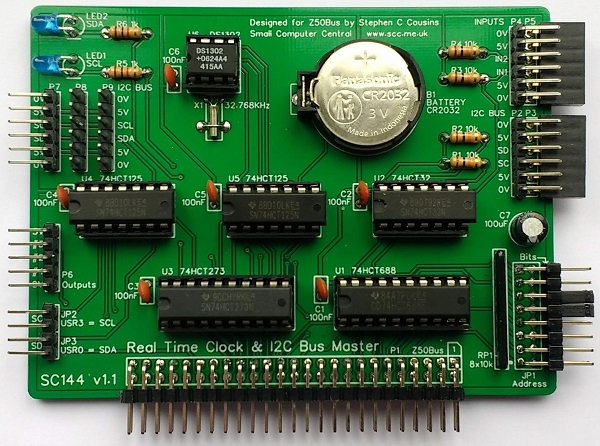

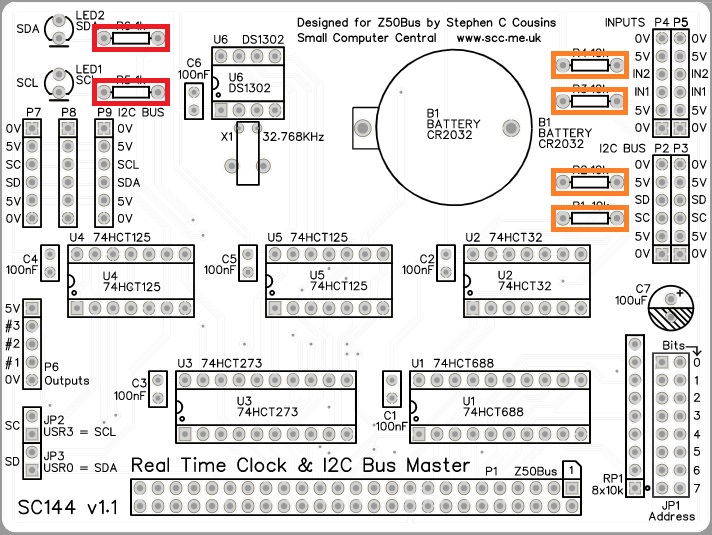

The picture below shows what a completed SC144, RTC & I2C Card should look like.

Resistors

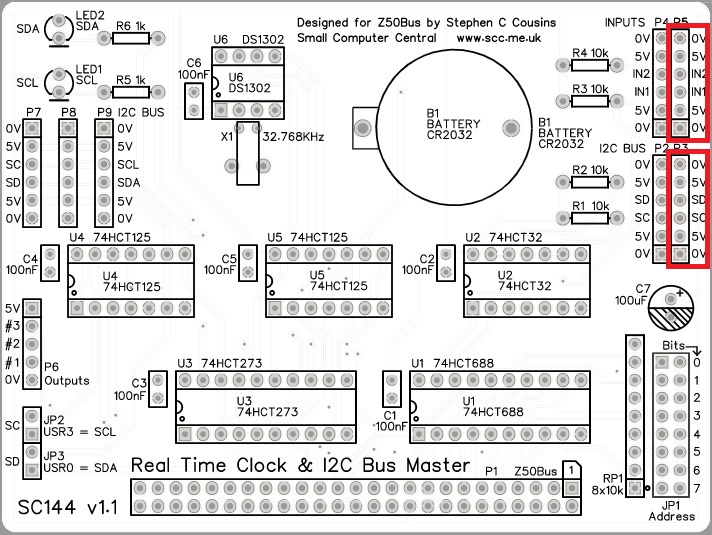

Fit and solder the 10k resistors, R1 to R4 (shown below in orange).

Fit and solder the 1k resistors, R5 and R6 (shown below in red).

Resistors can be fitted either way around, as they are not polarity dependent.

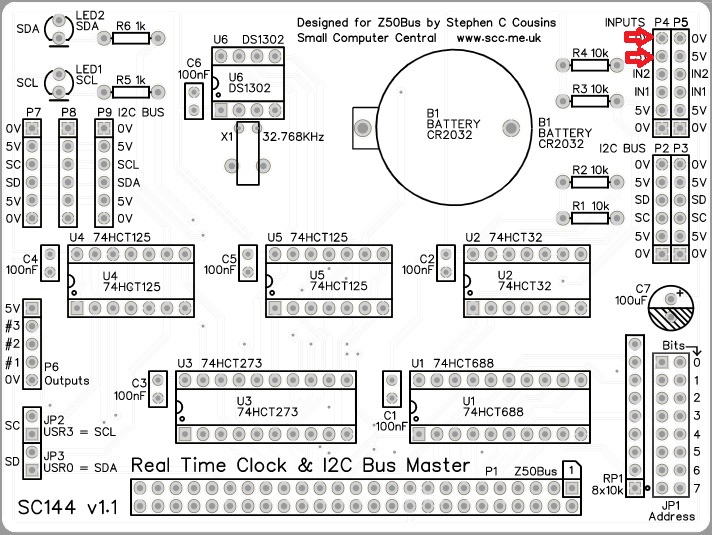

Sockets (6-pin)

Fit and solder the 6-pin angled sockets, P3 and P5.

Ensure the socket lays flat against the circuit board.

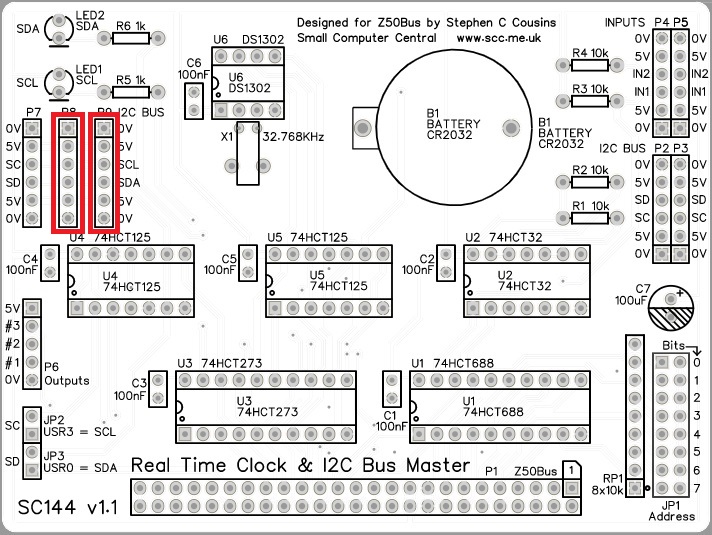

Single row angled header pins

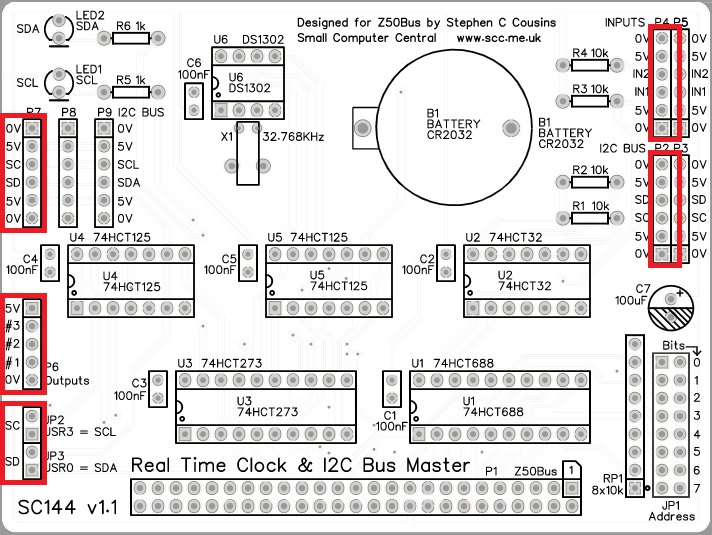

Fit and solder the single row angled header pins, P2, P4, P6, P7, JP2, and JP3.

Ensure the pins are parallel to the circuit board, especially P2 and P4.

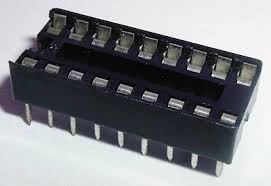

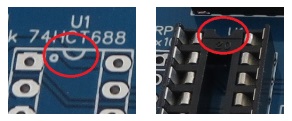

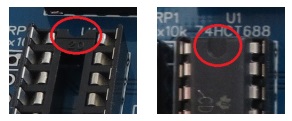

IC sockets

Fit and solder the IC sockets.

Be sure to fit them with the notch matching the legend on the circuit board, so you do not end up fitting the IC the wrong way around too.

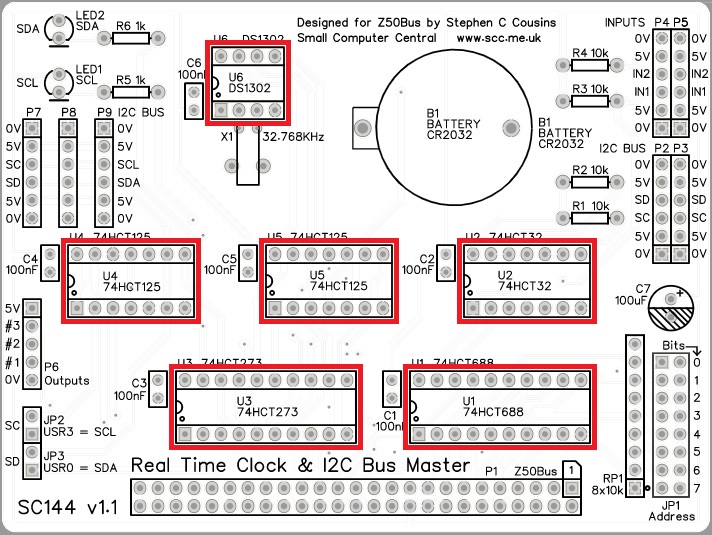

Resistor network

Fit and solder the 8x10k resistor network, RP1.

The 10k network will be marked 103.

Take care to fit the resistor network the correct way around. Pin 1 is usually marked with a dot. This end is indicated on the PCB and on the illustration below.

Double row angled header pins

Fit and solder the single row angled header pins, P1 and JP1.

Ensure the pins are parallel to the circuit board, especially P1.

Capacitor 100 nF (0.1 µF)

Fit and solder capacitors, C1 to C6.

This capacitor can be fitted either way around, as it is not polarity dependent.

The exact value of this component is not critical. The use of very cheap capacitors within the range of about 30 to 200 nF is acceptable.

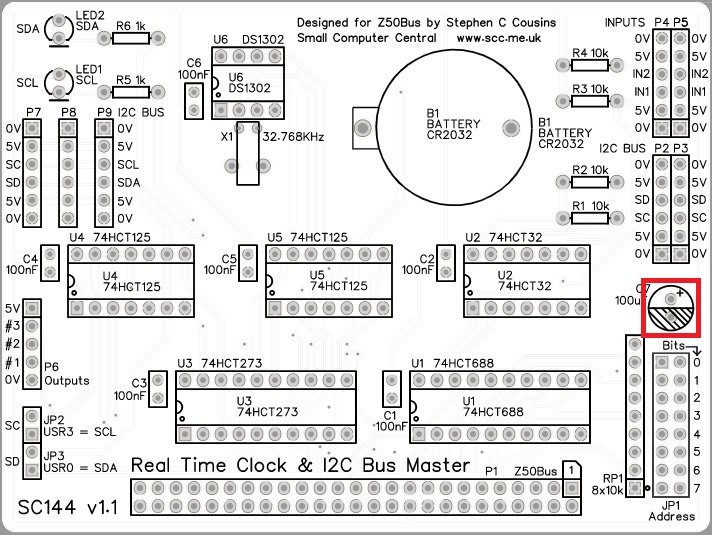

Capacitor 100 µF

Fit and solder capacitor, C7.

It is important to fit this capacitor the right way around. The negative terminal is indicated with a ‘minus’ sign, as illustrated to the right. The negative terminal also has a shorter lead.

The silkscreen has a plus sign for the positive terminal and a hashed area for the negative terminal

Light Emitting Diode (LED)

Fit and solder the light emitting diodes, LED1 and LED2.

It is important to fit the LED the correct way around. LEDs usually have a small flat side to indicate the cathode (the negative end). This should be positioned to match the flat side shown on the circuit board (illustrated to the right). Also, the cathode pin on the LED is usually shorter than the other pin (the Anode).

The LEDs can be fitted pointing vertically away from the circuit board or the leads can be bent so the LEDs face to the edge of the circuit board.

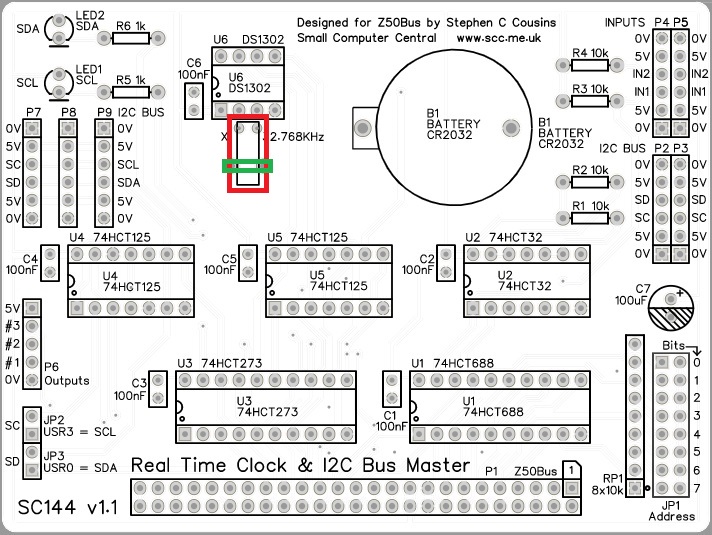

Crystal

Fit and solder the 32.768 kHz crystal, X1.

The crystal can be fitted either way around, as it is not polarity dependent.

The crystal can be secured in place with a small piece of wire fitted in the position indicated below in green. An off-cut resistor led is suitable for this.

Single row straight header pins

Fit and solder the single row straight header pins, P8 and P9.

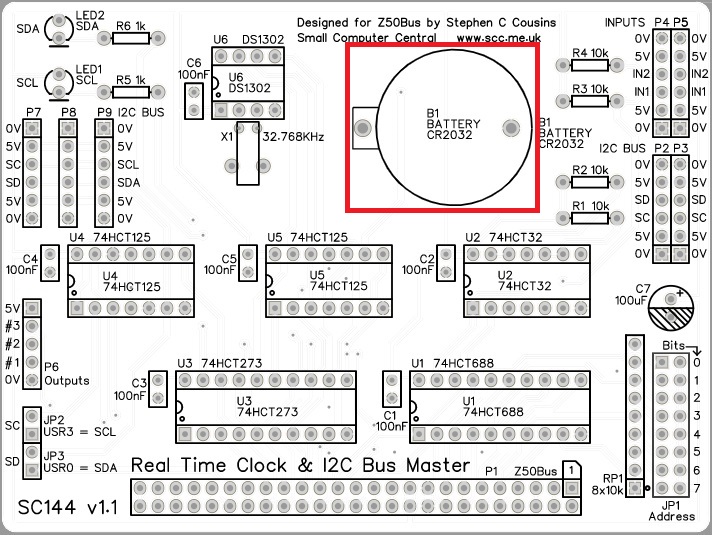

Battery holder

Fit and solder the CR2032 battery holder, B1.

Quick Tests

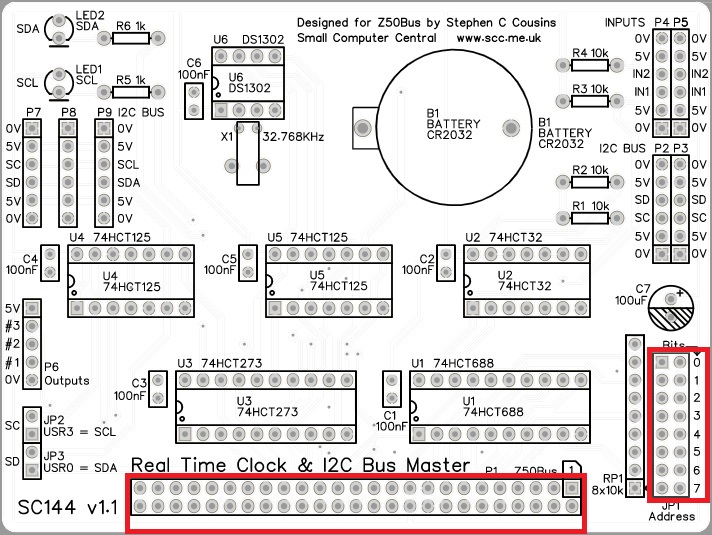

Repeat the check made earlier for a short on the power supply tracks. Connect the meter probes to the pins indicated below. This should be an open circuit, not a short. If you are using a digital meter set to measure resistance it will likely take a few seconds for the reading to stabilise as there are now capacitors on the power lines. A reading of more than 100k Ω (100000 ohms) is acceptable.

Inspection

Remove any solder ‘splats’ with a brush, such as an old toothbrush.

Visually inspect the soldering for dry joints and shorts.

Clean the flux off with suitable cleaning materials.

Visually inspect again.

Integrated Circuits

Insert the integrated circuits into their sockets, taking care to insert them the right way round, as illustrated below. Be careful not to bend any legs over.

Getting Started

The card’s I/O address needs to be set with jumper shunts on JP1.

The current software assumes the address is 0x0C. This can be set by fitting shunts in bit positions 2 and 3, as illustrated below. This may change in the future as the recommended I/O map for Z50Bus systems is to have the processor or SBC use the lower 64 I/O addresses.

Use with SC140 Z180 SBC/processor card: RomWBW firmware should now identify the real time clock at start up. RomWBW does not currently offer specific support for I2C so this is left to the user and the application software.

Use with Z80 based systems: There is not currently any firmware support for the real time clock or the I2C bus master. This is left to the user and the application software.

Both processor types allow use of the I2C bus master with existing example software for SC400 series I2C modules.

Notes

- This design is made with the permission of LiNC (designers of the Z50Bus).

- This product is designed for hobby use and is not suitable for industrial, commercial or safety-critical applications.

- The product contains small parts and is not suitable for young children.